Automobile Rearview Mirror Housing Parts Manufacturer and Supplier

We are manufacturer with high-precision processing equipment can make rearview car mirror mold. Automotive rearview mirrors are generally composed of mirror rings, pedestals, mirror housings, brackets, rotating shafts, and mirror mounts. The rearview mirror product has strict appearance requirements, high with general surface fine grain treatment, and low with general paint treatment. Depending on the model, the rearview mirrors are split and integrated. The mid-range and high-end models are split-type and the low-end models are integrated.

| Technical Parameters | |

| Mold Standard | DME,HASCO,LKM Meusburger etc. |

| Cavity/core steels | 1.2738, NAK80 and NAK55, 718H, 738H, 1.2344, P20HH, P20LQ, 1.2311, 1.2312, 1.2316, S136, 402H, 1.2343,1.1730, ASSAB8047, etc |

| Mold Base | 1.1730/420H/2085/P20/S136 etc |

| Mold construction | 2-plate mold, 3-plate mold |

| Cavity | Single-cavity, Multi-cavities |

| Finish | Anodized, Polish, Silk-screen, Painting, etc |

| Runner | Cool/Hot |

| Hardened | 42-48 HRC |

| Est. Slider/ Lifter needed | Injection Pin or injection plate |

| Design Software | CAD, ProE, UG,Solidwork, etc |

| Product Materials | ABS, PP, PE, POM, PMMA, etc |

Professional plastic injection mold and molding manufacturer

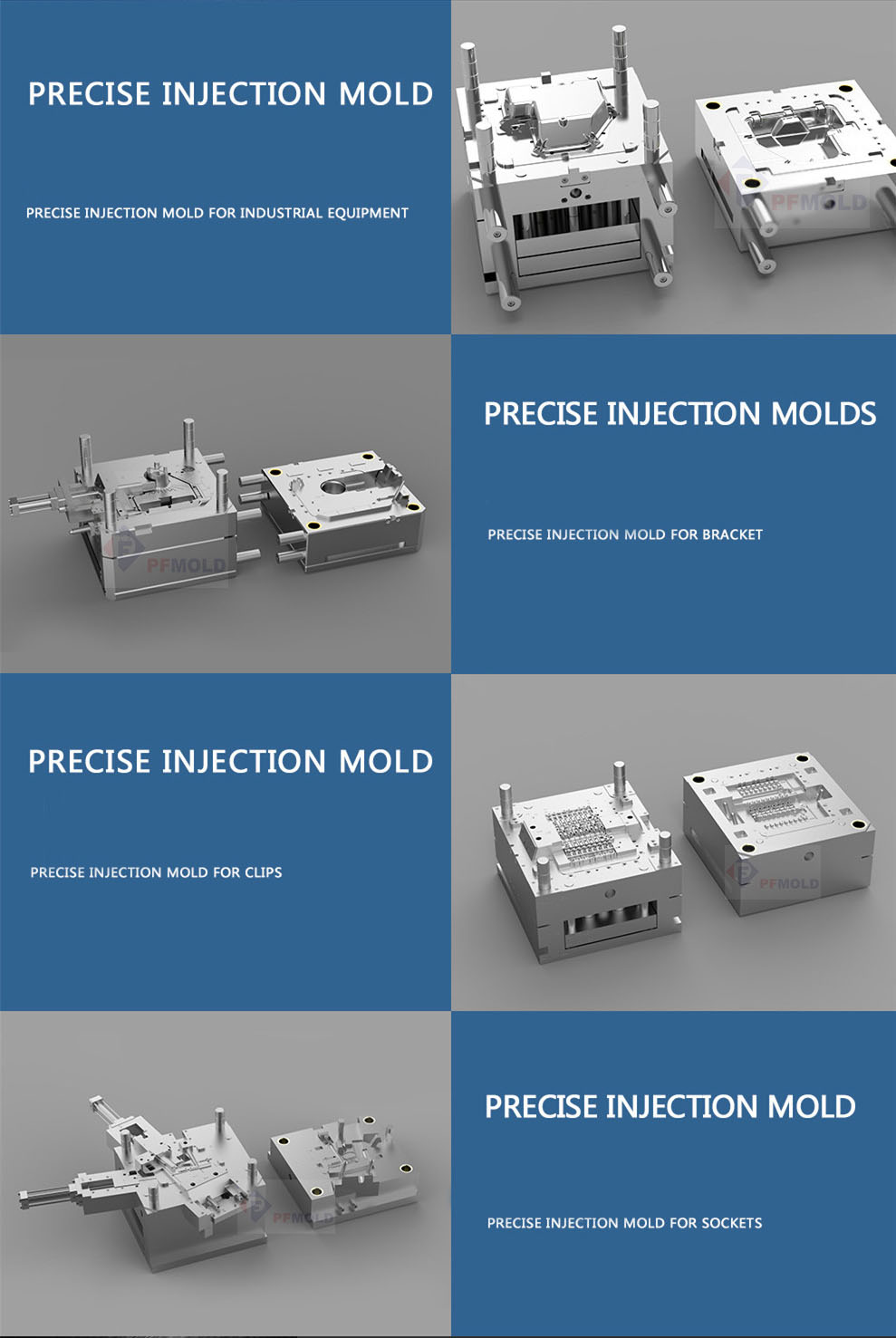

Plastic injection mold and parts

Precision injection mold and parts

2K mold and parts and overmolding service

Silicone molds and parts

Rapid prototyping tooling and parts, machining parts and 3D printing parts

IMD/IML mold and parts

1. Good quality, competitive price and good service

2. 20+ years experience on providing one-stop services( plastic part design---rapid prototype---mold making---production---delivery)

3. Good R&D team, provide DFM and mold flow etc.

4. One Window of client, easy to communicate.

5. Short lead time and on time delivery

6. Good after sales service

Spare parts offering, like: spring, ejector pins…

Mold maintenance as much as possible

Mold and plastic part design available

Prototype: CNC, SLC, SLS available

Injection molding available

Looking for ideal Bluetooth Speaker Cover Manufacturer & supplier?

We have a wide selection at great prices to help you get creative. All the Bluetooth Speaker Mold are quality guaranteed. We are China Origin Factory of Speaker Plastic Cover Molding. If you have any question, please feel free to contact us.