Let’s Get Your Precision Molding Project Started.

Precision molding requires knowledge, skill and a clear focus on innovation and adaptability. The PF team applies all of these traits to every project:

We combine a high degree of industry knowledge with a commitment to continuous improvement.

The end result is a team of professionals conversant with the latest precision molding technologies and able to devise new solutions for design challenges.

Innovations in high-performance thermoplastics affect our industry.

We keep ourselves informed of new developments so that we can continue to manufacture superior products suited to the environment in which they will be used.

Adept in developing proprietary technology, we have proven ourselves capable of delivering the right solution at the right time for even the most demanding projects.

Our reputation in plastic injection molding speaks for itself:

●Timely delivery of parts

● Consistent high quality in all parts

● Insulation of electrical components

● Proprietary equipment that reduces waste and saves customers money

● Strict quality control procedures

● ISO, TS, AS certified

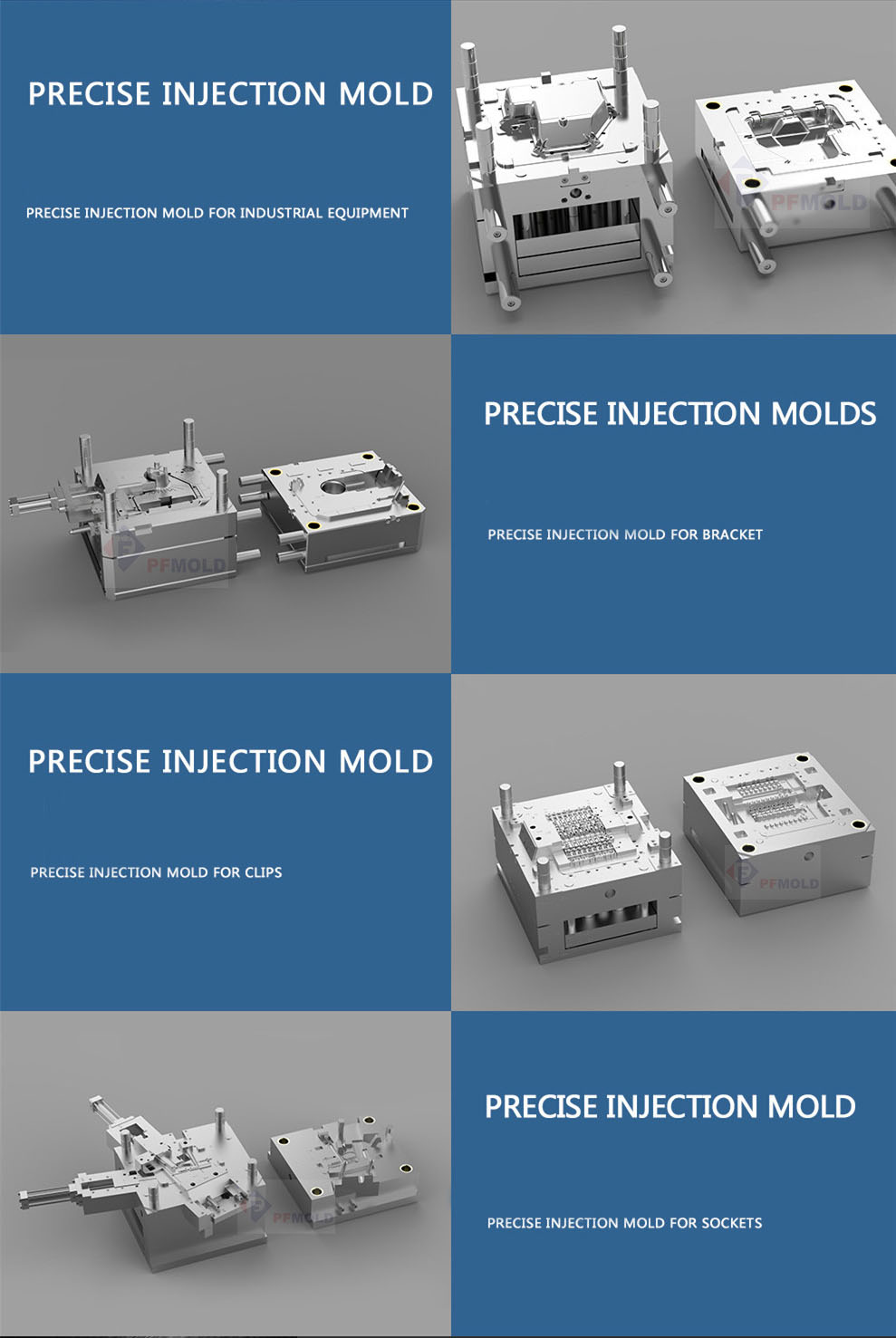

PF Mold can also support Precision Mold parts, such as Core pin, Ejector pin, die punch, Mold parts, Mold components, Non-standard Precision Parts, plastic mold parts, press die mold parts, Auto Machine Part. Ejector Sleeve. locating Block. Slide Block. Slide Retainer. Latch lock. Slide Lock, Sprue Bush, Locating Ring, Date Stamp, Air Valves, Guide Bush, Cooling Nipple, manufacturer and supplier, at present, the mould accessories products are mainly divided into Non-standard mold parts, Plastic mould parts, Press die mold parts, Die Springs, welcome to know more about the customization.

Specializing in mold engineering and modeling, we also provide reverse engineering, prototyping, as well as full part development services. An ISO certified company, we pride ourselves on delivering quality tools and precision plastic parts on time and within budget.

Why choose PF MOLD to work together from your hundreds of potential suppliers list ?

1- Professional engineers and international project management team to work out your project.

2- Project Schedule Report with photos is sent to buyer weekly to report the schedule for his project.

3- Support multi payment terms: T/T, Western Union, PayPal.

4- High Quality: all of our products with 1 year warranty.

5- Low MOQ: the initial order quantity for injection Plastic Molding is 300 pieces.

6- Soonest Delivery: the best Mold Making lead time is 15 days.

7- Best Service: All inquiries will be replied within 12 hours.

8- Quality Control: We have gotten the ISO9001:2000 Certificate and it is effective through January 11, 2012.

9- After-sales service: We have arranged some specialized workers to keep after-sales service.

10- Clients Reference: If you need some clients to take references, we will send the contact details to you after we get the permission from our clients.

11- Free Design: We have many kinds of Mold Design software which can open all kinds of files, and we will design the 3D drawings freely for you as well.

12- A Professional international project management team who works 16 hours per day in 2 shifts to ensure every project or client's question will get a fast and responsible reply within 3 hours.