High Quality Medical Injection Molding - Medical Device Injection Molding. one stop shop for molding and tooling – PF Mold

High Quality Medical Injection Molding - Medical Device Injection Molding. one stop shop for molding and tooling – PF Mold Detail:

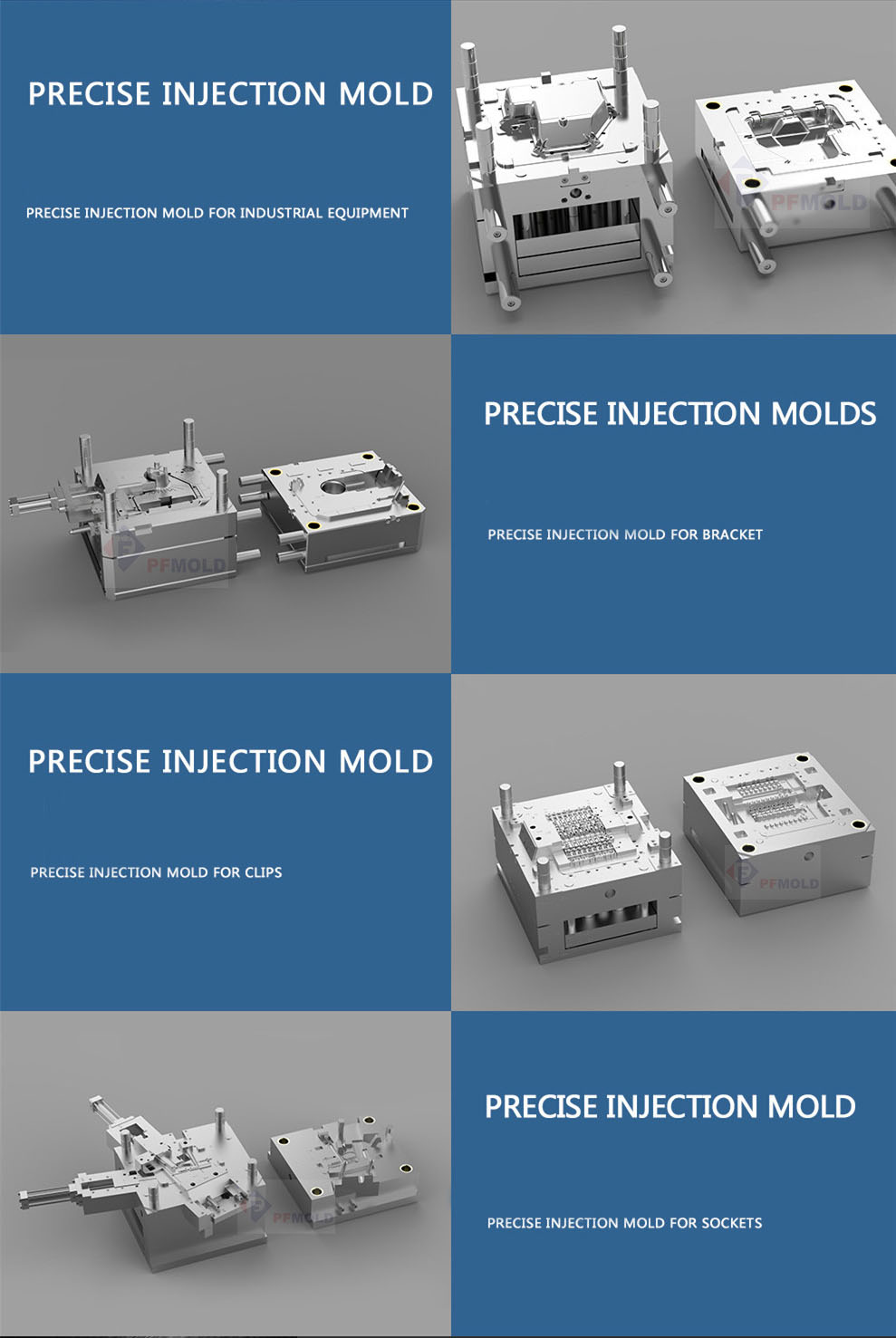

We can provide custom mold service for a single component or many plastic parts projects, whether the part is small or large, simple plastic part or complex structure component, our professional plastic mold design and engineering team will serve you the best custom mold and molding solutions. Medical device molds are precision, high-demand injection molds, the molding process has high requirements, PF Mold in medical device product development has a wealth of experience, raw materials are usually PC, ABS or PC/ABS, surface treatment is usually texture or mirror SPI A1. Therefore, improving the experience of parts and mold design is important for obtaining beautiful parts after injection molding, and mold manufacturing suppliers will need a wealth of experience. At PF, you’ll have a one-stop solution to save time and reduce risk. Mold design usually takes 1 week to complete, but for medical purposes, many tests are required after first of trial. PF has the patience and technology to provide customers with multiple mold modification and sampling.

| Technical Parameters | |

| Name: | Plastic injection part for medical field /Medical parts; |

| Standard | HASCO, DME, MISUMI, JIS, LKM, etc. |

| Mold tooling equipment | Lathe, Milling,Grinder,Drill,CNC,EDM,Wire cut machine,Punch machine |

| Maximum mold size | 1500*1500 mm |

| Validation | IQ/OQ/PQ Validation, Per Customer Requirements |

| Service | Independent R&D, part development. |

| Material | resin ABS, silicone, PA6 and PC. |

| Package: | Sterilization and non-sterilization general packaging per client’s idea or request. |

| Certification | ISO 13485 |

| Major markets | The United States, European Countries |

1. Medical injection molds are versatility

2. Medical injection mold is easy to disinfect

3. Higher security

4. Injection molding medical products improve the quality of life

5. High-cost performance

6. Environmental protection

7. Medical device injection molding has potential for future innovation

1. Patient care series

2. Diagnostic equipment series

3. Drug filtration series

4. Shell and component series

5. Disposable medical supplies series

6. Surgical instrument series

7. Orthopedics product series

8. Heart product series

9. Ophthalmology treatment instrument series

10. Healthcare components and equipment series

The medical device injection molding parts are highly specialized and precise, and have precise and detailed requirements for sterility and supervision, these requirements are much higher comparing other industries. A dust-free injection molding shop can help ensure that particulate matter, that is dust, airborne organics, or vaporized particles will not contaminate the plastics that will make up medical device injection molding components.

Product detail pictures:

Related Product Guide:

Our staff are usually in the spirit of "continuous improvement and excellence", and while using the top-quality high-quality items, favorable value and superior after-sales services, we try to acquire each and every customer's belief for High Quality Medical Injection Molding - Medical Device Injection Molding. one stop shop for molding and tooling – PF Mold , The product will supply to all over the world, such as: Brasilia, Belgium, Thailand, To keep the leading position in our industry, we never stop challenging the limitation in all aspects to create the ideal products. In his way, We can enrich our life style and promote a better living environment for the global community.

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.