China wholesale Cnc Automation - Auto Headlight Mould, China car Headlight parts molding Manufacturers – PF Mold

China wholesale Cnc Automation - Auto Headlight Mould, China car Headlight parts molding Manufacturers – PF Mold Detail:

For cars, lamps are an indispensable feature. No matter whether it is a traditional or technologically-stylish model, the most important parts of the lamp are headlight body, reflector, decorative frame and lamp lens. As the automotive exterior parts in highest demand, the design and manufacturing requirements for lamps are also very high.

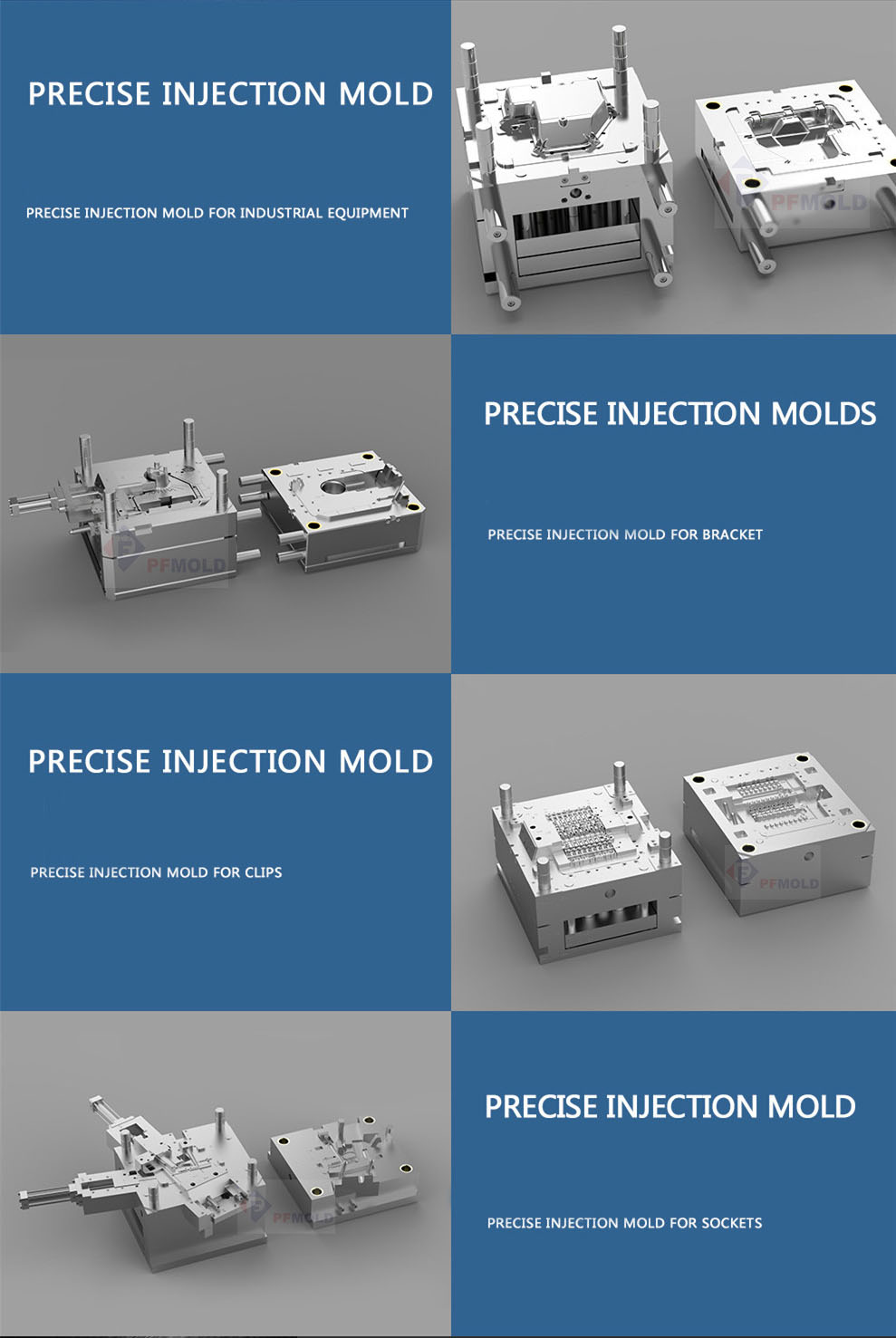

PF mold are capable of making molds for automotive lamp mold, OEM automotive lamp mold,Automotive headlamp mold,Automotive taillamp mold,F og lamp mold,Day running light mold,Light guide bar mold,Lense mold,Two color rotation mold.

| Technical Parameters | |

| Mold material | P20 steel, 718, 2738, H13, NAK80, 2344, 2343, S136, etc . |

| Product material | ABS,PA,PA66+GF,POM,PC,PP,PET,TPE,PVC,HDPE,etc |

| Standard | HASCO, DME, MISUMI, JIS, LKM, etc. |

| Mold tooling equipment | Lathe, Milling,Grinder,Drill,CNC,EDM,Wire cut machine,Punch machine |

| Maximum mould size | 1500*1500 mm |

| Gate | Side Gate, Sub Gate, Direct Gate, Hook Gate, Pin Point Gate, etc. |

| Cavity | Single or Multi cavities |

| Mold Life45#: | 300,000 to 500,000 shots |

| P20: | 600,000 shots |

| 718: | 800,000shots |

| Package | Wooden packing box or as customer’s requirements |

- Car parts molds making.

- After market car parts molds making.

- Gas-assist injection mold design and mold making.

- High gloss polishing molds making.

- Semi-product assembly.

- Semi-product painting & coating.

- Customer design service.

- Prototyping.

- Mold making.

- Manufacturing process control.

- Mold flow analysis service available !

- Reverse engineering.

- Customer molding & assembly.

- Cold runner mold and hot runner mold

Looking for ideal Bluetooth Speaker Cover Manufacturer & supplier?

We have a wide selection at great prices to help you get creative. All the Bluetooth Speaker Mold are quality guaranteed. We are China Origin Factory of Speaker Plastic Cover Molding. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

We'll make every effort and hard work to be superb and excellent, and speed up our steps for standing inside the rank of intercontinental top-grade and high-tech enterprises for China wholesale Cnc Automation - Auto Headlight Mould, China car Headlight parts molding Manufacturers – PF Mold , The product will supply to all over the world, such as: Swaziland, Rio de Janeiro, Bulgaria, Our products are widely recognized and trusted by users and can meet continuously changing of economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.