A Guide China has become a global manufacturing hub, providing high-quality and cost-effective solutions to various industries.

When it comes to tool and die manufacturing, finding skilled professionals is critical to ensuring accuracy and efficiency. Here are some key steps to help you find a skilled tool and die maker in China: Research and identify potential suppliers: Start by conducting thorough research to identify potential tool and die manufacturers in China. Look for a company with a good reputation, extensive experience, and a track record of successfully delivering high-quality products. Use online directories, industry forums, and trade associations to gather information about reputable suppliers

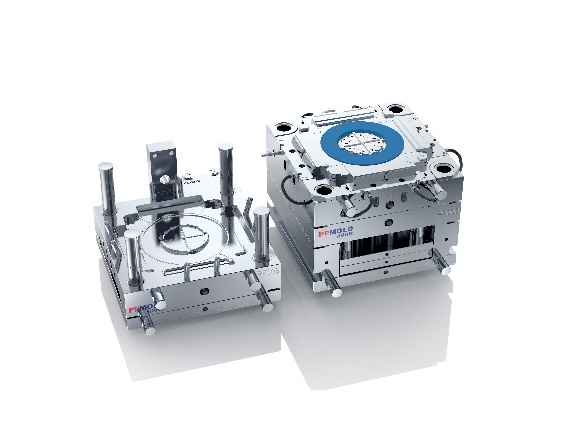

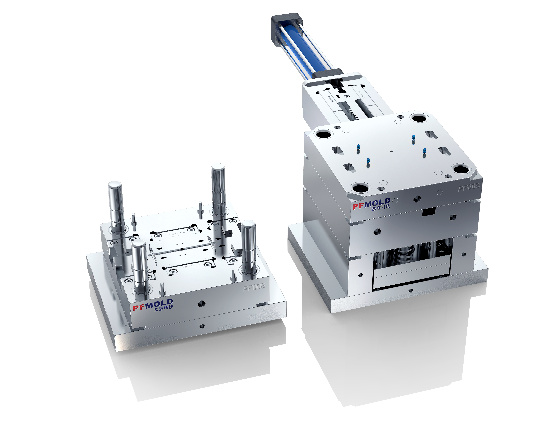

Assess manufacturing capabilities: Assess the manufacturing capabilities of potential suppliers. Look for companies with advanced machinery, technology and fully equipped workshops. Make sure they have experience machining complex tool and die components and can meet your specific requirements. Review portfolios and case studies: Request portfolios and case studies from shortlisted vendors to evaluate their past projects. Evaluate the quality, precision and innovation of their work. Pay attention to the industries they have served and the projects they have completed, as this will give you an idea of their expertise. Request Samples: Request samples of tool and mold components from potential suppliers. Evaluate samples for quality, durability and finish.

If possible, conduct tests to ensure they meet your specifications and standards. Check Certifications and Credentials: Make sure the tool and die manufacturer you are considering has the necessary certifications and credentials. Look for ISO certifications, quality management systems and any other relevant industry-specific certifications. This ensures that suppliers adhere to international standards and best practices. Visit manufacturing facilities: If feasible, plan to visit the manufacturing facilities of the shortlisted vendors. This will give you direct insight into their infrastructure, functionality, and quality control processes. Meeting the team and discussing your requirements in person can also help build a strong working relationship.

Ask for References: Ask potential vendors for references from their current or past clients. Contact these references to gather information about the vendor's professionalism, reliability, and customer service. This can provide valuable insights into their performance. Negotiate terms and pricing: Once you find the right tool and die manufacturer in China, negotiate terms and pricing. Discuss factors such as project timelines, payment terms, manufacturing capabilities, and any additional services they can provide.

Make sure you have a clear understanding of the costs involved and the supplier's policies. Sign a detailed agreement: Before the project begins, sign a detailed agreement outlining all agreed terms, specifications, delivery schedules and quality control measures. This will help avoid any misunderstandings or disputes in the future. Regular communication and quality monitoring: Maintain regular communication with tool and mold manufacturers throughout the manufacturing process. Regular quality checks are performed to ensure components meet your expectations.

Address any questions or concerns promptly to keep the production process running smoothly. Finding skilled tool and mold manufacturers in China requires careful research, due diligence and effective communication.

By following these steps, you can feel confident selecting a reliable supplier who can efficiently and effectively meet your tool and mold manufacturing needs.

Post time: Oct-13-2023